Being the topmost Teflon lining supplier in Turkey, we introduce quality excellence, durability, and service in tune with stringent industrial standards. Teflon lining is indeed a process to apply a layer of PTFE lining inside the equipment, pipes, and fittings for providing tremendous resistance against extremely corrosive and aggressive chemicals. Since Teflon lining has non-reactive and non-stick qualities, it protects from damage and makes items safer, longer under the tough conditions of industries. Pharmaceutical, chemical processing, petrochemicals, water treatment, oil & gas, and others are a few of the industries which make extensive use of Teflon-lined systems for the treatment of acids, solvents, and other poisonous media. Teflon is used for hostile media owing to its superior chemical resistance, wide tolerance for temperature, low friction, and non-contaminative properties. It prevents corrosion, contamination, and degradation of the material effectively while providing assured performance at low maintenance costs. We provide Teflon lining solutions made from a wide range of base metals, Mild Steel (MS), Stainless Steel (SS), and Carbon Steel (CS)—design-engineered to client specifications.

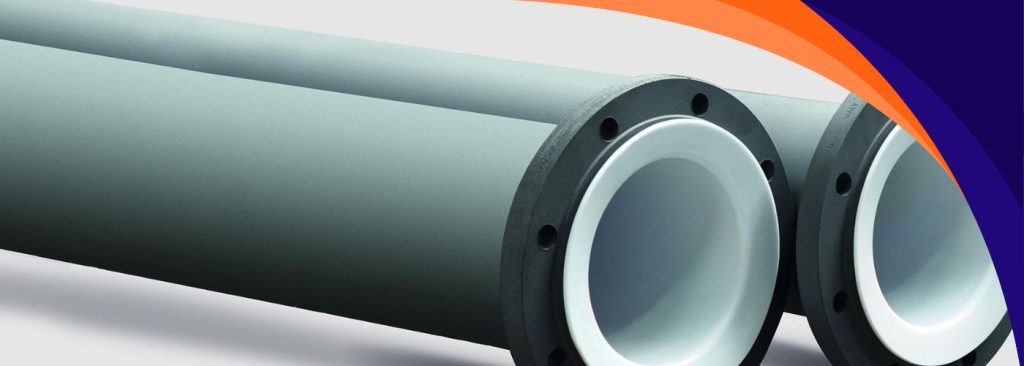

A Teflon lined pipe is a metal pipe lined with PTFE (Polytetrafluoroethylene) also commonly known as Teflon internally in a bid to guarantee high chemical resistance and corrosion resistance. The lining creates a non-reactive barrier between the interior metal surface of the pipe and aggressive media such as acids, solvents, or corrosive gases. Teflon lined pipes enjoy wide applications in chemical processing, pharma, oil and gas, and waste treatment plants where purity and durability are of highest priority. Combining the non-stick and non-corrosive properties of Teflon with base metals such as MS, SS, or CS ensures safe and long-lasting fluid handling.

Emre PTFE Telfon Lining is a leading supplier of SS PTFE Telfon Lined Pipes in Turkey, Istanbul, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

| Size (NB) | øA±1 | øB | øC | PCD | øE | G | No. of Holes | Holes Dia | Pipe THK. K | Liner THK. S | Face THK. H |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 MM | 14 | 21 | 34.9 | 60.3 | 88.9 | 11.1 | 4 | 15.9 | 2.9 | 4 | 2.4 |

| 20 MM | 19.6 | 26.6 | 42.7 | 69.8 | 98.4 | 12.7 | 4 | 15.9 | 3.4 | 4 | 2.4 |

| 25 MM | 19.6 | 26.6 | 50.8 | 79.4 | 108 | 14.2 | 4 | 15.9 | 3.4 | 4 | 2.4 |

| 32 MM | 28.1 | 35.1 | 63.5 | 88.9 | 117.5 | 15.8 | 4 | 15.9 | 3.6 | 4 | 2.4 |

| 40 MM | 33.9 | 40.9 | 73 | 98.4 | 127 | 17.5 | 4 | 15.9 | 3.7 | 4 | 2.4 |

| 50 MM | 45.5 | 52.5 | 92.1 | 120.7 | 152.4 | 19.1 | 4 | 19 | 3.9 | 4 | 2.4 |

| 65 MM | 55.7 | 62.7 | 104.8 | 139.7 | 177.8 | 22.2 | 4 | 19 | 5.2 | 4 | 2.4 |

| 80 MM | 70.9 | 77.9 | 127 | 152.4 | 190.5 | 23.8 | 4 | 19 | 5.5 | 4 | 2.4 |

| 100 MM | 95.3 | 102.3 | 157.2 | 190.5 | 228.6 | 23.8 | 8 | 19 | 6 | 4 | 2.4 |

| 125 MM | 119.2 | 128.2 | 185.7 | 215.9 | 254 | 23.8 | 8 | 22.2 | 6.6 | 5 | 3.8 |

| 150 MM | 145.1 | 154.1 | 215.9 | 241.3 | 279.4 | 25.4 | 8 | 22.2 | 7.1 | 5 | 3.8 |

| 200 MM* | 197.4 | 206.4 | 269.9 | 298.5 | 342.9 | 28.6 | 8 | 22.2 | 6.35 | 5 | 3.8 |

| 250 MM* | 249.3 | 260.3 | 323.9 | 362 | 406.4 | 30.2 | 12 | 25.4 | 6.35 | 6 | 4 |

| 300 MM* | 300.1 | 311.1 | 381 | 431.8 | 482.6 | 31.8 | 12 | 25.4 | 6.35 | 6 | 4 |

| 350 MM* | 328.7 | 339.7 | 412.8 | 476.3 | 533.4 | 34.9 | 12 | 28.6 | 7.92 | 6 | 4 |

| 400 MM* | 379.5 | 390.5 | 469.9 | 539.8 | 596.9 | 36.5 | 16 | 28.6 | 7.92 | 6 | 4 |

| 450 MM* | 429.3 | 441.3 | 533.4 | 577.9 | 635 | 39.7 | 16 | 31.8 | 7.92 | 6.5 | 4.4 |

| 500 MM* | 475.9 | 488.9 | 584.2 | 635 | 698.5 | 42.9 | 20 | 32 | 9.52 | 7 | 4.8 |

| 600 MM* | 575.9 | 590.5 | 692.2 | 749.3 | 812.6 | 47.6 | 20 | 35 | 9.52 | 8 | 5.6 |

| 700 MM | 685.1 | 692.1 | 801.6 | 863.6 | 827.1 | 50 | 28 | 35 | 9.52 | 4 | 2.4 |

| 800 MM | 786.7 | 793.7 | 916.2 | 977.9 | 1060.4 | 50 | 28 | 41.3 | 9.52 | 4 | 2.4 |

Teflon (PTFE) resists a wide range of corrosive chemicals, acids, and solvents, making it ideal for harsh industrial environments.

The smooth, non-stick inner surface reduces flow resistance, prevents buildup, and improves fluid efficiency.

Teflon performs reliably across a wide temperature range (typically -20°C to +200°C), maintaining integrity under thermal stress.

PTFE lining is non-reactive and inert, ensuring purity of media—critical for pharmaceuticals, food, and high-purity chemical applications.

It’s a metal pipe internally lined with PTFE (commonly known as Teflon) to protect against chemical corrosion.

Excellent chemical resistance, high-temperature tolerance, non-stick surface, and long service life.

Usually carbon steel (MS) or stainless steel (SS), depending on the application.

Yes, when designed correctly, they can handle up to 10–16 bar pressure depending on size and spec.

Teflon lined pipes can typically withstand temperatures from -20°C to +200°C, depending on pressure and media compatibility.

We are the leading Manufacturer and Supplier of PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Turkey, Istanbul.

© Emre PTFE Lining. All Rights Reserved