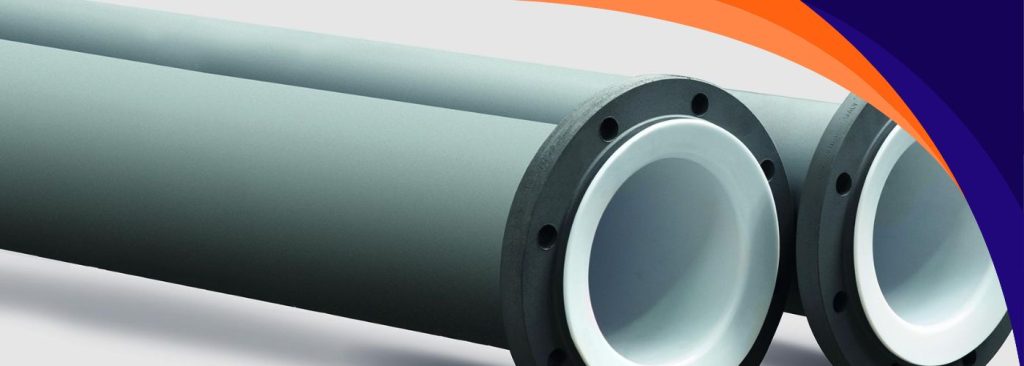

We are a reliable SS PTFE lined pipe manufacturer located in Turkey, offering superior corrosive and high-temperature usage solutions. Our pipes feature double protection with the best stainless steel grades SS 304 and SS 316 lined with the best-quality PTFE to deliver superior chemical resistance and extreme temperature resistance.They are designed to be sanitary and durable and can be utilized in pharmaceutical and food-grade processing industries where purity and safety are critical. With the quality commitment and innovation-driven strong emphasis, our PTFE lined pipes guarantee long-term operation with reduced maintenance cost and enhanced operation efficiency in most industrial applications.

SS PTFE lined pipe is an internally lined stainless steel (SS) pipe with a very non-reactive and chemically resistant fluoropolymer polytetrafluoroethylene (PTFE). The union brings together the toughness and strength of stainless steel with corrosion resistance and non-stick nature of PTFE. They have widespread application in chemical processing, pharmaceutical, and food processing operations where aggressive chemicals or high purity are employed. The PTFE lining keeps metal safe from chemical attack, conserves maintenance, and yields longer life. SS PTFE lined pipes are ideally applicable for safe and efficient transfer of corrosive, toxic, or high-purity fluids.

Size : 25 NB to 450 NB

Pipe Material : 106 grade B Sch 40 from 25 NB to 150 NB

Flanges Used : ASTM A 105/IS 2062

Hydro Test : at 29.8 Kg/cm2

Spark Test : 15 KVA

PIPE : 1. SEAMLESS CS ASTM A106 GR.B, SCH.-40, 2. ASTM A312 TP 304, SCH.-40

FLANGE : 1. IS 2062 / ASTM A105, 2. ASTM A351 GR. CF8

Lining Material Options

PFA – ASTM D 3307

FEP – ASTM D 2116

ETFE – ASTM D 3159

PVDF – ASTM D 3322

PP – ASTM D 4101

HDPE

Emre PTFE Lining is a leading supplier of SS PTFE Lined Pipes in Turkey, Istanbul, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

| SIZE | Min. Avail Length with flange | Max. Length Avail. | Flange Stopper Thik “J” | Wgt per mtr length | Wgt + ~ 1 mtr | |

| NB | INCH | (mm) | (mm) | (mm) | (Kg) | (Kg) |

| 25 | 1″ | 100 | 6000 | 10 | 5.5 | 3.3 |

| 40 | 1.5″ | 100 | 6000 | 10 | 8.5 | 5.5 |

| 50 | 2″ | 100 | 6000 | 10 | 11.0 | 6.5 |

| 80 | 3″ | 110 | 6000 | 10 | 20.0 | 13.0 |

| 100 | 4″ | 110 | 6000 | 10 | 30.0 | 18.5 |

| 150 | 6″ | 125 | 6000 | 10 | 48.7 | 33.8 |

| 200 | 8″ | 125 | 6000 | 12 | 75.5 | 52.0 |

| 250 | 10″ | 140 | 3000 | 12 | 98.5 | 62.5 |

| 300 | 12″ | 150 | 3000 | 12 | 120.0 | 82.0 |

| 350 | 14″ | 200 | 3000 | 12 | 157.0 | 84.0 |

| 400 | 16″ | 200 | 1500 | 12 | 192.0 | 95.6 |

| 450 | 18″ | 210 | 500 | 15 | 214.0 | 108.0 |

| 600 | 24″ | 240 | 500 | 15 | 335.0 | 145.0 |

PTFE lining resists a wide range of aggressive chemicals, acids, and solvents.

PTFE prevents material buildup, improving flow efficiency and reducing maintenance

Ideal for both high and low temperature applications, from cryogenic to elevated heat.

Reduced repair, replacement, and downtime costs over the system’s lifetime.

It’s a stainless steel (SS) pipe with an internal PTFE lining to provide chemical resistance and durability.

SS offers better mechanical strength, corrosion resistance, and longevity, especially in high-purity or hygienic applications.

Common in pharmaceuticals, food processing, biotech, and high-end chemical industries.

Typically available from DN15 to DN600, with pressure ratings up to 10–16 bar, depending on design.

Yes, all SS PFA lined pipes are provided with vent holes for easy leak detection. We follow stringent quality control protocols to ensure defect-free products.

We are the leading Manufacturer and Supplier of PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Turkey, Istanbul.

© Emre PTFE Lining. All Rights Reserved