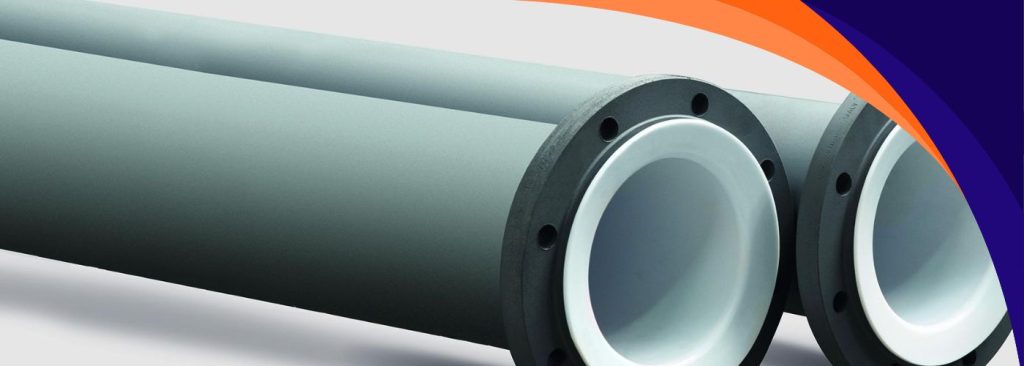

As a prominent producer and supplier of MS PTFE-lined pipes in Turkey, we offer cost-effective, high-performance piping solutions for chemical processing, pharmaceuticals, petrochemicals, and other demanding uses. Our products are designed to offer long-term protection, reduced maintenance costs, and safe, reliable fluid transportation. PTFE-lined pipes combine the strength of mild steel (MS) with the superior chemical resistance of PTFE. The MS base provides mechanical strength and structural longevity, while the PTFE lining provides superior resistance to corrosive chemicals, heat, and abrasive media. Its double-layer construction makes it the ideal choice for aggressive industrial applications.

MS PTFE lined pipe consists of mild steel (MS) pipe lined with the inside with polytetrafluoroethylene (PTFE), a fluoropolymer of high performance with excellent resistance to chemicals and non-stick character. The lining protects the steel from corrosive chemicals, and the pipe is therefore ideal for transporting aggressive acids, bases, and solvents in chemical processing, pharmaceutical, and food processing industries. PTFE lining provides a smooth inert surface, while the outer casing of MS adds mechanical strength. These together offer durability, safety, and longevity in abusive surroundings where regular metal or plastic pipe would compromise their lifespan immediately.

Size : 25 NB to 450 NB

Pipe Material : 106 grade B Sch 40 from 25 NB to 150 NB

Flanges Used : ASTM A 105/IS 2062

Hydro Test : at 29.8 Kg/cm2

Spark Test : 15 KVA

PIPE : 1. SEAMLESS CS ASTM A106 GR.B, SCH.-40, 2. ASTM A312 TP 304, SCH.-40

FLANGE : 1. IS 2062 / ASTM A105, 2. ASTM A351 GR. CF8

Lining Material Options

PFA – ASTM D 3307

FEP – ASTM D 2116

ETFE – ASTM D 3159

PVDF – ASTM D 3322

PP – ASTM D 4101

HDPE

Emre PTFE Lining is a leading supplier of MS PTFE Lined Pipes in Turkey, Istanbul, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

|

NB

|

ID

|

RF

|

OD

|

PCD

|

No.Of Holes x Dia Of Holes

|

Lining Thickness Standard

|

Lining Thickness Full Vacuum

|

Length Max.

|

| 15 | 10.80 | 34.90 | 88.9 | 60.3 | 4×15.9 | 3.0 | 3.1 | 3000 |

| 20 | 16.00 | 42.70 | 98.4 | 69.8 | 4X15.9 | 3.0 | 3.1 | 3000 |

| 25 | 20.15 | 50.80 | 108.0 | 79.4 | 4X15.9 | 3.2 | 3.5 | 3000 |

| 40 | 33.90 | 73.00 | 127.0 | 98.4 | 4X15.9 | 3.2 | 3.5 | 3000 |

| 50 | 45.50 | 92.10 | 152.4 | 120.7 | 4X19 | 3.5 | 4.6 | 3000 |

| 65 | 55.68 | 104.80 | 177.8 | 139.7 | 4×19 | 3.5 | 4.8 | 3000 |

| 80 | 70.90 | 127.00 | 190.5 | 152.4 | 4X19 | 3.5 | 5.0 | 3000 |

| 100 | 94.30 | 157.20 | 228.6 | 190.5 | 8X19 | 4.0 | 5.8 | 3000 |

| 150 | 114.10 | 215.90 | 279.5 | 241.3 | 8X22.2 | 5.0 | 6.8 | 3000 |

| 200 | 195.10 | 269.90 | 342.9 | 298.5 | 8X22.2 | 5.0 | 7.9 | 2000 |

| 250 | 247.40 | 323.90 | 406.4 | 362.0 | 12X25.4 | 5.0 | 8.8 | 2000 |

| 300 | 297.00 | 381.00 | 482.6 | 431.8 | 12X25.4 | 5.0 | 9.0 | **** |

Superior protection against corrosive chemicals.

Reduces friction and enhances flow efficiency.

Withstands high temperatures (up to 260°C) and high pressures.

More affordable than expensive alloys, offering similar performance.

It’s a mild steel (MS) pipe internally lined with PTFE (Polytetrafluoroethylene) to provide chemical resistance.

PTFE lining offers excellent corrosion resistance, extending pipe life in harsh chemical environments.

Commonly used in chemical processing, pharmaceuticals, petrochemicals, and food industries.

It is usually mechanically locked or flared at ends to prevent movement, not chemically bonded.

The PTFE lining is usually formed using a paste extrusion or isostatic molding process, then sintered (heat-treated) and mechanically locked into the steel pipe. This ensures strong adhesion and resistance to delamination under pressure or temperature fluctuations.

We are the leading Manufacturer and Supplier of PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Turkey, Istanbul.

© Emre PTFE Lining. All Rights Reserved