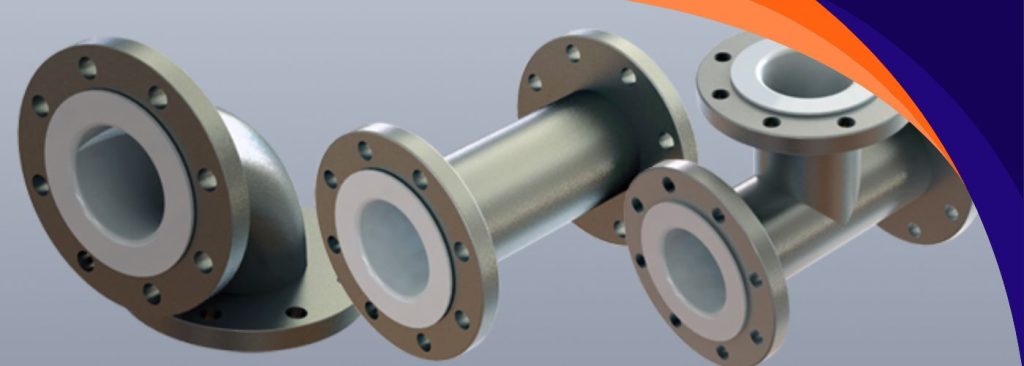

As one of the top Turkish HDPE-lined fittings manufacturers, we focus on delivering creative anti-corrosion products to the oil & gas, mining, water treatment, and chemical processing industries. By utilizing our HDPE lining technology, we fortify steel fittings to increase their resistance to chemicals and longevity against hostile operating environments. With proprietary methods such as high-pressure insertion or thermal forming, we form a leak-free, seamless junction between the HDPE liner and the steel body. In various diameters and wall thicknesses, our fittings are compliant with international standards and have a rating of up to 100 bar pressure. Our fittings lined with HDPE are intended for long-term service life and have lower maintenance, greater service life, and consistent flow under extreme conditions.

HDPE lined fittings are applied where corrosion resistance, chemical compatibility, and long-term durability are essential. Employed widely in oil & gas, mining, water treatment, and chemical processing industries, they create an internal barrier to aggressive fluids, slurries, or corrosive gases. They are ideal for systems handling abrasive or highly reactive materials, extending the life of metal components while maintaining structural integrity. They are particularly suitable for high-pressure situations, withstanding up to 100 bar, and in applications where low maintenance and stable flow are necessary. HDPE-lined fittings offer an economic way of handling difficult pipeline conditions, offering leak-proof performance and lowered downtime in demanding industrial applications.

| O.D | PN 2.5 | PN 4 | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | (12) | (13) | (14) | (15) | ||

| 20 | – | – | – | – | – | – | – | – | 2.3 | 2.8 | 2.7 | 3.2 | 3.4 | 4.0 | ||

| 25 | – | – | – | – | – | – | 2.3 | 2.8 | 2.8 | 3.3 | 3.4 | 4.0 | 4.2 | 4.9 | ||

| 32 | – | – | – | – | 2.3 | 2.7 | 3.0 | 3.5 | 3.6 | 4.2 | 4.4 | 5.0 | 5.4 | 6.2 | ||

| 40 | – | – | 2.0 | 2.4 | 2.8 | 3.3 | 3.7 | 4.3 | 4.5 | 5.1 | 5.5 | 6.2 | 6.7 | 7.6 | ||

| 50 | – | – | 2.4 | 2.9 | 3.5 | 4.1 | 4.6 | 5.3 | 5.6 | 6.4 | 6.8 | 7.7 | 8.4 | 9.5 | ||

| 63 | 2.0 | 2.4 | 3.0 | 3.5 | 4.4 | 5.1 | 5.8 | 6.6 | 7.0 | 7.9 | 8.6 | 9.6 | 10.5 | 11.8 | ||

| 75 | 2.3 | 2.7 | 3.6 | 4.2 | 5.3 | 6.0 | 6.9 | 7.8 | 8.4 | 9.4 | 10.2 | 11.4 | 12.5 | 14.0 | ||

| 90 | 2.8 | 3.2 | 4.3 | 5.0 | 6.3 | 7.2 | 8.2 | 9.3 | 10.0 | 11.2 | 12.2 | 13.6 | 15.0 | 16.7 | ||

| 110 | 3.4 | 3.9 | 5.3 | 6.0 | 7.7 | 8.7 | 10.0 | 11.2 | 12.3 | 13.7 | 14.9 | 16.6 | 18.4 | 20.5 | ||

| 125 | 3.8 | 4.4 | 6.0 | 6.8 | 8.8 | 9.4 | 11.4 | 12.8 | 13.9 | 15.5 | 16.9 | 18.8 | 20.9 | 23.2 | ||

| 140 | 4.3 | 4.9 | 6.7 | 7.6 | 9.8 | 11.0 | 12.8 | 14.3 | 15.6 | 17.4 | 19.0 | 21.1 | 23.4 | 26.0 | ||

| 160 | 4.9 | 5.6 | 7.7 | 8.6 | 11.2 | 12.5 | 14.6 | 16.3 | 17.8 | 19.8 | 21.7 | 24.0 | 26.7 | 29.6 | ||

| 180 | 5.5 | 6.2 | 8.6 | 9.7 | 12.6 | 14.1 | 16.4 | 18.3 | 20.0 | 22.2 | 24.4 | 27.0 | 30.0 | 33.2 | ||

| 200 | 6.1 | 6.9 | 9.6 | 10.7 | 14.0 | 15.6 | 18.2 | 20.3 | 22.3 | 24.7 | 27.1 | 30.0 | 33.4 | 37.0 | ||

| 225 | 6.9 | 7.7 | 10.8 | 12.0 | 15.7 | 17.5 | 20.5 | 22.8 | 25.0 | 27.7 | 30.5 | 33.7 | 37.5 | 41.0 | ||

| 250 | 7.6 | 8.6 | 11.9 | 13.3 | 17.5 | 19.4 | 22.8 | 25.3 | 27.8 | 30.8 | 33.8 | 37.4 | 41.7 | 46.1 | ||

| 280 | 8.5 | 9.6 | 13.4 | 14.9 | 19.6 | 21.7 | 25.5 | 28.3 | 31.2 | 34.5 | 37.9 | 41.9 | 46.7 | 51.6 | ||

| 315 | 9.6 | 10.7 | 15.0 | 16.7 | 22.0 | 24.4 | 28.7 | 31.8 | 35.0 | 38.7 | 42.6 | 47.1 | 52.5 | 58.0 | ||

| 355 | 10.8 | 12.1 | 16.9 | 18.8 | 24.8 | 27.5 | 32.3 | 35.8 | 39.5 | 43.7 | 48.0 | 53.0 | 59.2 | 65.4 | ||

| 400 | 12.2 | 14.2 | 19.1 | 22.1 | 28.0 | 32.3 | 36.4 | 42.1 | 44.5 | 51.4 | 54.1 | 62.4 | – | – | ||

| 450 | 13.7 | 15.9 | 21.5 | 25.0 | 31.4 | 36.3 | 41.0 | 47.4 | 50.0 | 57.7 | – | – | – | – | ||

| 500 | 15.2 | 17.7 | 23.9 | 27.6 | 34.5 | 40.4 | 45.5 | 52.6 | 55.6 | 64.1 | – | – | – | – | ||

| 560 | 17.0 | 19.8 | 26.7 | 30.9 | 39.1 | 45.2 | 51.0 | 58.9 | – | – | – | – | – | – | ||

| 630 | 19.1 | 22.2 | 30.0 | 34.7 | 44.0 | 50.8 | 57.3 | 66.1 | – | – | – | – | – | – | ||

| 710 | 21.6 | 25.0 | 33.9 | 39.1 | 49.6 | 57.2 | – | – | – | – | – | – | – | – | ||

| 800 | 24.3 | 28.1 | 38.1 | 44.1 | 55.9 | 64.4 | – | – | – | – | – | – | – | – | ||

| 900 | 27.3 | 31.6 | 42.9 | 49.9 | – | – | – | – | – | – | – | – | – | – | ||

| 1000 | 30.3 | 35.1 | 47.7 | 55.0 | – | – | – | – | – | – | – | – | – | – | ||

Emre PTFE Lining is a leading supplier of HDPE Lined Fittings in Turkey, Istanbul, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

| O.D | PN 2.5 | PN 4 | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | (12) | (13) | (14) | (15) |

| 20 | – | – | – | – | – | – | – | – | – | – | 2.3 | 2.7 | 2.8 | 3.3 |

| 25 | – | – | – | – | – | – | – | – | 2.3 | 2.7 | 2.8 | 3.3 | 3.5 | 4.0 |

| 32 | – | – | – | – | – | – | 2.4 | 2.9 | 3.0 | 3.4 | 3.6 | 4.2 | 4.5 | 5.1 |

| 40 | – | – | – | – | 2.3 | 2.7 | 3.0 | 3.5 | 3.7 | 4.3 | 4.5 | 5.1 | 5.6 | 6.3 |

| 50 | – | – | 2.3 | 2.8 | 2.9 | 3.4 | 3.8 | 4.4 | 4.6 | 5.3 | 5.6 | 6.4 | 6.9 | 7.8 |

| 63 | – | – | 2.5 | 3.0 | 3.6 | 4.2 | 4.7 | 5.4 | 5.8 | 6.6 | 7.0 | 7.9 | 8.7 | 9.8 |

| 75 | – | – | 2.9 | 3.4 | 4.3 | 4.9 | 5.6 | 6.4 | 6.9 | 7.8 | 8.4 | 9.4 | 10.4 | 11.6 |

| 90 | 2.3 | 2.8 | 3.5 | 4.1 | 5.1 | 5.8 | 6.7 | 7.6 | 8.2 | 9.3 | 10.0 | 11.2 | 12.5 | 16.9 |

| 110 | 2.7 | 3.2 | 4.3 | 5.0 | 6.3 | 7.1 | 8.2 | 9.3 | 10.0 | 11.2 | 12.3 | 13.8 | 15.2 | 16.9 |

| 125 | 3.1 | 3.7 | 4.9 | 5.6 | 7.1 | 8.0 | 9.3 | 10.5 | 11.4 | 12.8 | 13.9 | 15.5 | 17.3 | 19.2 |

| 140 | 3.5 | 4.1 | 5.4 | 6.2 | 8.0 | 9.0 | 10.4 | 11.7 | 12.8 | 14.3 | 15.6 | 17.4 | 19.4 | 21.5 |

| 160 | 4.0 | 4.6 | 6.2 | 7.1 | 9.1 | 10.2 | 11.9 | 13.3 | 14.6 | 16.3 | 17.8 | 19.8 | 22.1 | 24.5 |

| 180 | 4.4 | 5.1 | 7.0 | 7.9 | 10.2 | 11.5 | 13.4 | 15.0 | 16.4 | 18.3 | 20.0 | 22.2 | 24.9 | 27.6 |

| 200 | 4.9 | 5.6 | 7.7 | 8.7 | 11.4 | 12.7 | 14.9 | 16.6 | 18.2 | 20.3 | 22.3 | 24.7 | 27.6 | 30.6 |

| 225 | 5.5 | 6.3 | 8.7 | 9.8 | 12.8 | 14.3 | 16.7 | 18.6 | 20.5 | 22.8 | 25.0 | 27.7 | 31.1 | 34.4 |

| 250 | 6.1 | 7.0 | 9.7 | 10.9 | 14.2 | 15.8 | 18.6 | 20.7 | 22.8 | 25.3 | 27.8 | 30.8 | 34.5 | 38.2 |

| 280 | 6.9 | 7.8 | 10.8 | 12.1 | 15.9 | 17.7 | 20.8 | 23.1 | 25.5 | 28.3 | 31.2 | 34.5 | 38.7 | 42.7 |

| 315 | 7.7 | 8.7 | 12.2 | 13.7 | 17.9 | 20.0 | 23.4 | 26.0 | 28.7 | 31.8 | 35.0 | 38.7 | 43.5 | 48.0 |

| 355 | 8.7 | 9.8 | 13.7 | 15.3 | 20.1 | 22.3 | 26.3 | 27.2 | 32.3 | 35.8 | 39.5 | 43.6 | 49.0 | 54.1 |

| 400 | 9.8 | 11.5 | 15.4 | 18.0 | 22.7 | 26.3 | 29.7 | 34.4 | 36.4 | 42.1 | 44.5 | 51.4 | 55.2 | 63.7 |

| 450 | 11.0 | 12.9 | 17.4 | 20.3 | 25.5 | 29.5 | 33.4 | 38.7 | 41.0 | 47.4 | 50.0 | 57.7 | – | – |

| 500 | 12.2 | 14.3 | 19.3 | 22.4 | 28.4 | 32.8 | 37.1 | 42.9 | 45.5 | 52.5 | 55.6 | 64.1 | – | – |

| 560 | 13.7 | 16.0 | 21.6 | 25.1 | 31.7 | 36.7 | 41.5 | 58.0 | 51.0 | 58.8 | – | – | – | – |

| 630 | 15.4 | 18.0 | 24.3 | 28.2 | 35.7 | 41.3 | 46.7 | 54.0 | 57.3 | 66.1 | – | – | – | – |

| 710 | 17.4 | 20.3 | 27.4 | 31.8 | 40.2 | 46.5 | 52.6 | 60.7 | – | – | – | – | – | – |

| 800 | 19.6 | 22.2 | 30.8 | 35.7 | 45.3 | 52.3 | – | – | – | – | – | – | – | – |

| 900 | 22.0 | 25.5 | 34.7 | 40.2 | 51.0 | 58.8 | – | – | – | – | – | – | – | – |

| 1000 | 24.2 | 28.3 | 38.5 | 44.5 | 56.7 | 65.3 | – | – | – | – | – | – | – | – |

Designed to withstand high pressures, ensuring long-term performance in demanding environments

Highly resistant to chemical corrosion, providing longevity in aggressive environments

Compatible with fusion welding, mechanical coupling, and adhesive bonding for seamless integration

Requires minimal upkeep, leading to lower maintenance costs over time

HDPE lined fittings are steel or metal fittings internally lined with High-Density Polyethylene (HDPE) to resist corrosion, abrasion, and chemical attack in pipeline systems

They offer excellent chemical resistance, long service life, reduced maintenance, and a smooth internal surface for improved flow efficiency.

They are widely used in industries like mining, chemical processing, wastewater treatment, and slurry transport where aggressive media are present.

HDPE has a maximum operating temperature of about 60°C (140°F), so they’re not ideal for high-temperature applications.

The metal portion can be welded using standard practices, but care must be taken not to damage the HDPE liner. Field repairs of the liner itself are limited and usually require specialized tools or returning the item to the manufacturer.

We are the leading Manufacturer and Supplier of PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Turkey, Istanbul.

© Emre PTFE Lining. All Rights Reserved