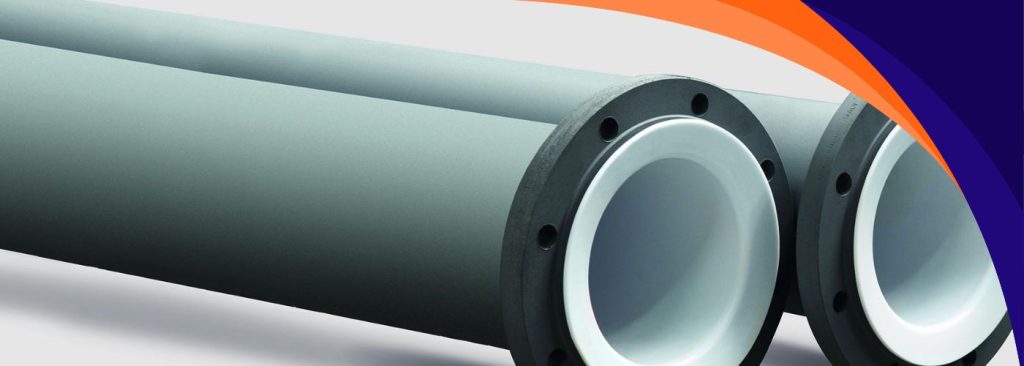

We are one of the top manufacturers of HDPE Lined Pipes in Turkey, dealing in the provision of anti-corrosion piping solutions that find application in the oil & gas sector, mining, water treatment, and chemical process industry. HDPE lining increases steel pipe lifespan while providing strength along with even more chemical resistance. Our innovative proprietary lining technology encompasses high pressure insertion or heat forming for an leak-tight union. With diameters and thicknesses made available, our pipes contain global standards of a maximum of 100 bar pressure ratings. Our HDPE-lined pipes are designed to withstand extreme conditions, offering long-lasting performance, reduced maintenance, and reliable fluid transport over varied applications.

Use HDPE (High-Density Polyethylene) when a strong, economical, and resistant plastic to chemicals is required for general-purpose applications such as containers, piping, and wear strips. It holds up at low to moderate temperatures (up to ~120°C) and can be easily processed.

Choose PTFE (Polytetrafluoroethylene) where outstanding chemical resistance, high-temperature stability (up to ~260°C), and an extremely low friction coefficient are critical—ideal for seals, gaskets, and non-stick or sliding uses. PTFE is more expensive and less mechanically resilient than HDPE but works better in demanding applications.

HDPE-lined pipe is a steel pipe internally lined with High-Density Polyethene (HDPE). This combination brings the durability of steel and the lubricity and corrosion resistance of HDPE. HDPE-lined pipes are used in slurry, mining, water, and chemicals transportation where internal abrasion or corrosion is a concern. The HDPE liner is put inside the steel pipe and then expanded to a close fit. This system prolongs the pipe life, minimizes maintenance, and maximizes flow efficiency in harsh or abrasive applications. It is best suited for high-performance long-term piping applications.

Emre PTFE Lining is a leading supplier of HDPE Lined Pipes in Turkey, Istanbul, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

| Standard Liner Thk. | Heavy* | |||||

|---|---|---|---|---|---|---|

| 1 (25) | 21 | 51 | 3.0 | 4 | 100 | 6000 |

| 11/2 (40) | 34 | 73 | 3.0 | 4 | 100 | 6000 |

| 2 (50) | 46 | 92 | 3.0 | 4.5 | 150 | 6000 |

| 21/2 (65) | 59 | 105 | 3.0 | 4.0 | 150 | 6000 |

| 3 (80) | 74 | 127 | 3.0 | 5.0 | 150 | 6000 |

| 4 (100) | 96 | 157 | 3.0 | 6.0 | 150 | 6000 |

| 6 (150) | 144 | 212 | 5.0 | 7.0 | 150 | 6000 |

| 8 (200) | 194 | 270 | 5.0 | 7.0 | 200 | 6000 |

| 10 (x250) | 242 | 324 | 6.0 | 8.0 | 200 | 6000 |

| 12 (x300) | 292 | 381 | 6.0 | 9.0 | 200 | 6000 |

Designed to withstand high pressures, ensuring long-term performance in demanding environments

Highly resistant to chemical corrosion, providing longevity in aggressive environments

Compatible with fusion welding, mechanical coupling, and adhesive bonding for seamless integration

Requires minimal upkeep, leading to lower maintenance costs over time

An HDPE lined pipe consists of a host pipe (usually steel) lined internally with High-Density Polyethylene (HDPE) to combine the strength of steel with the corrosion resistance of plastic.

HDPE lining provides excellent resistance to corrosion, abrasion, and chemicals, while also improving flow efficiency and extending pipe service life.

HDPE liner is installed using a tight-fit method such as roll-down (swagelining) or thermoplastic reversion, where the liner is temporarily reduced in size, inserted into the host pipe, then allowed to expand or is pressurized to form a tight fit.

The lining is inserted using methods like tight-fit lining (thermoplastic reversion), where HDPE is temporarily reduced in size, inserted, and then expanded to fit tightly inside the host pipe.

Depending on the application and environment, HDPE lined pipes can last 50+ years, especially in non-UV exposed and chemically stable environments.

We are the leading Manufacturer and Supplier of PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Turkey, Istanbul.

© Emre PTFE Lining. All Rights Reserved