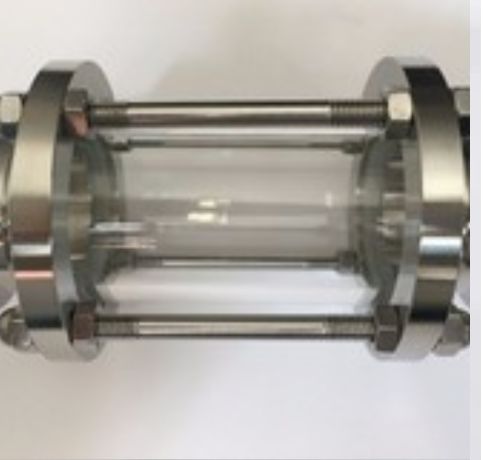

PTFE Lined Tubular Sight GlassPTFE-lined tubular sight glasses provide unobstructed visual observation of the flow of fluid in pipelines combined with excellent chemical resistance and life. The lining of PTFE provides protection against corrosion due to aggressive chemicals and is accordingly best suited in chemical, pharma and food processing applications. They are weightless easy to fit and maintain and need negligible maintenance. They ensure safe non-reactive monitoring in acid alkali and solvent systems. Their high temperature and pressure resistance enhance operating reliability and safety, and offer efficient process monitoring in extreme conditions.

PTFE lined tubular sight glass is a technologically advanced industrial device utilized for visual monitoring of the flow of liquid in pipelines. It is a clear glass tube encased within a protective PTFE (Polytetrafluoroethylene) coating to enhance chemical resistance and prevent corrosion when utilized with aggressive or hazardous chemicals. The PTFE coating makes it particularly acceptable for use in the pharmaceuticals, chemicals and food processing industries. It has excellent visibility of the flowing medium with safety and long life under high pressure, temperature, and chemically reactive conditions. It promises constant performance in demanding applications.

| Size | : | ½” to 12” (15 NB to 300 NB) |

| Manufacturing Standard | : | ASME 16.5, Class 150# |

| Body & Lining | : | MS/DI/CS/SS PTFE/ FEP/ PFA/ PVDF |

| Design | : | Fixed Flange End |

| Pressure | : | Metal Body with lining 5~10 kg/cm² Metal Body without lining 28kg/cm² |

Emre PTFE Lining is a leading supplier of PTFE Lined Tubular Sight Glass in Turkey, Istanbul, offering high-quality, corrosion-resistant solutions ideal for chemical, pharmaceutical, and industrial applications.

B – 1 | SIGHT GLASS | ||

C – 2 | |||

15 | 50 | ||

25 | 25 | 65 | 89 |

15 | – | – | |

40 | 25 | 75 | 102 |

40 | – | – | |

15 | – | – | |

50 | 25 | 85 | 114 |

40 | – | – | |

15 | – | – | |

80 | 25 | 110 | 140 |

40 | – | – | |

15 | – | – | |

100 | 25 | 130 | 165 |

40 | – | – | |

15 | – | – | |

150 | 25 | 170 | 203 |

40 | – | – | |

15 | – | – | |

200 | 25 | 200 | 279 |

40 | – | – | |

15 | – | – | |

250 | 25 | 250 | 279 |

40 | – | – | |

15 | – | – | |

300 | 25 | 276 | 305 |

40 | – | – | |

PTFE lining provides excellent resistance to corrosive chemicals, ensuring durability even in harsh environments.

PTFE withstands high temperatures, making it suitable for processes involving heat-intensive operations.

PTFE lining minimizes risks of leaks or contamination, ensuring safe operation in critical systems.

The smooth, non-stick surface of PTFE minimizes residue buildup, reducing cleaning and maintenance efforts.

It’s used to visually inspect the flow and condition of corrosive or high-purity fluids in pipelines, typically in chemical or pharmaceutical applications.

PTFE (Polytetrafluoroethylene) provides excellent chemical resistance, preventing corrosion and contamination of the fluid being observed.

Yes, depending on the design, PTFE lined sight glasses can handle moderate to high temperatures (up to ~200°C) and pressures, but always check manufacturer specs.

It is typically installed between flanges in a pipeline using standard bolt patterns, with gaskets ensuring a leak-tight seal.

Yes, sight glasses are inspected for PTFE lining uniformity and adhesion to ensure durability, chemical resistance, and defect-free performance.

We are the leading Manufacturer and Supplier of PTFE Lined Pipe, Fittings, Flanges, Spool and Valves in Turkey, Istanbul.

© Emre PTFE Lining. All Rights Reserved